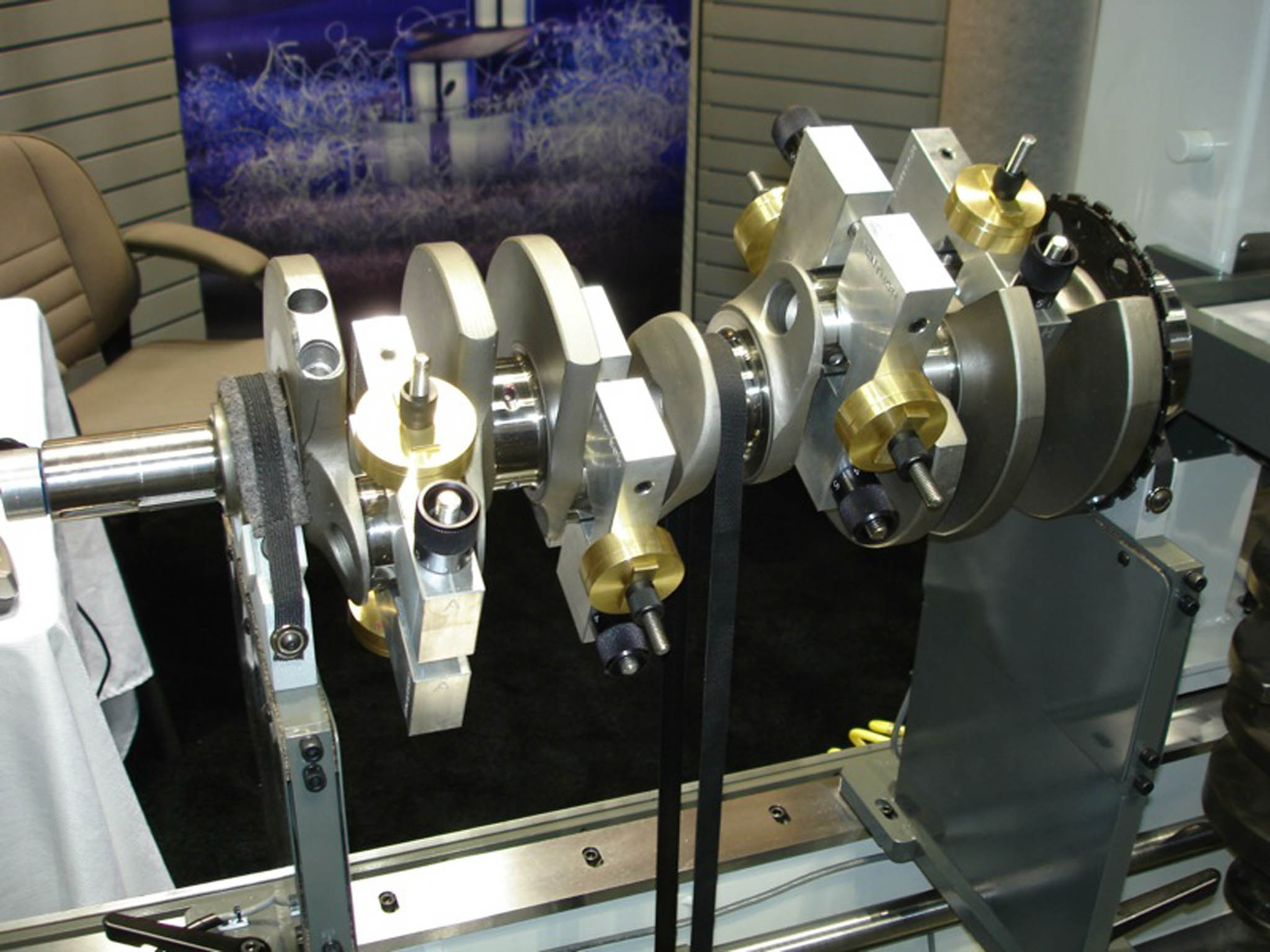

DCB-2000

Dynamic Crankshaft Balancing Machine

Fentech DCB-2000 Dynamic Crankshaft Balancing Machine.

Fentech’s top-of-the-line DCB-2000 Dynamic Crankshaft Balancer is the preferred choice of motorsport engine builders and high-performance engine rebuilders throughout the industry. The DCB-2000’s advanced software identifies critical areas of imbalance and indicates the appropriate corrective actions necessary to fine tune the balance of the crankshaft to your tightest tolerances, from 0.01 to 1,000 grams on workpieces weighing up to 500 pounds (226 kg.).

Designed and built right here in the USA, the Fentech’s DCB-2000 Dynamic Crankshaft Balancing machine gives you unmatched precision, quality and long-term durability, with simple functionality and helpful features to make your job easier.

Weight-A-Minute Advanced Software Technology

With Fentech’s exclusive Weight-A-Minute dynamic crankshaft balancer control software, you don’t need a master’s degree in Physics to produce incredibly well-balanced crankshafts, because the system guides you through everything! The advanced DCB-2000 Windows® based software is engineered and designed to incorporate the primary principles of physics and centripetal force that lie at the core of crankshaft balancing dynamics.

Check out these incredibly helpful Weight-A-Minute software capabilities:

- Bobweight Calculator computes and displays bobweight information to accurately simulate the rotating and reciprocating components that will be connected to the crankshaft when it’s in operation.

- Heavy Metal Calculator to give you the accurate weight measurements of heavy metals that need to be added to the crankshaft to bring it into balance.

- Drill Depth Calculator automatically calculates the drill depth for material removal to avoid costly mistakes.

- Flywheel Conversion Calculator to convert one neutrally balanced flywheel to another.

- Vectoring Application to relocate the imbalance on the crankshaft and adjust the location of the heavy spot.

- Graphic Displays provide easy-to-understand representations of setups, calibrations and unbalance while measuring.

- Balance File Index and System Memory that stores detailed crankshaft specifications, technical and setup information for easy recall and setup.

- Reciprocating Percent Data Storage retains critical balancing specifications for easy access and reference during and after the balancing process.

- EASE OF USE. Be up and running and precision-balancing crankshafts the same day you set it up.

World-Class* Precision-Performance That’s Simple to Use

Almost any shop technician can quickly gain proficiency with the system in just a few short hours, so you can install and set up in the morning and be cranking out precision-balanced crankshafts in the afternoon. And you can always count on the experts at Fentech for training and ongoing technical support.

*YES! We offer CE Marking to fulfill requirements for the EC Declaration of Conformity.

MORE Features Included with the Fentech DCB-2000 Dynamic Crankshaft Balancer.

- Automatic Speed Control offers added safety and precision. It selects and adjusts correct balancing speeds based on workpiece unbalance levels, and includes preset speeds of 350, 500 and 750 RPMs.

- Balance History storage to quickly access details on previous cycles or “spins” for reference during the balancing process. Printable crankshaft balance details can be printed out to show documentation to customers.

- Automatic Shutoff stops the machine automatically after completing measurements or if an unsafe condition occurs to allow for unattended operation.

- Bobweight Card computes and displays bobweight based on information entered.

- Automatic Add/Remove Weight Selection displays the proper angle and weight for material addition or removal at the touch of a button.

- Drill Depth Feature calculates proper drill depth for material removal, eliminating miscalculations.

- Heavy-Duty Drill Tower rotates 90 degrees and slides the full length of the machine to allow operator to easily drill and install heavy metal counter weights into crankshaft.

- Jog Button allows the workpiece to rotate slowly for verification of setup and belt alignment.

- Hard Bearing Design allows for greater sensitivity and precision resulting in highly accurate and repeatable measurements.

- Compact Size saves valuable floor space in your shop.

- Help Function with detailed instructions and information is always a click away.

(Already have an older Fentech/Sunnen Crankshaft Balancer? Contact us about an affordable UPGRADE to the latest, easy to use software to make your job even easier.)