Industrial Balancing Services

Fentech for Precision Industrial Balancing ServicesFentech for Precision Industrial Balancing Services

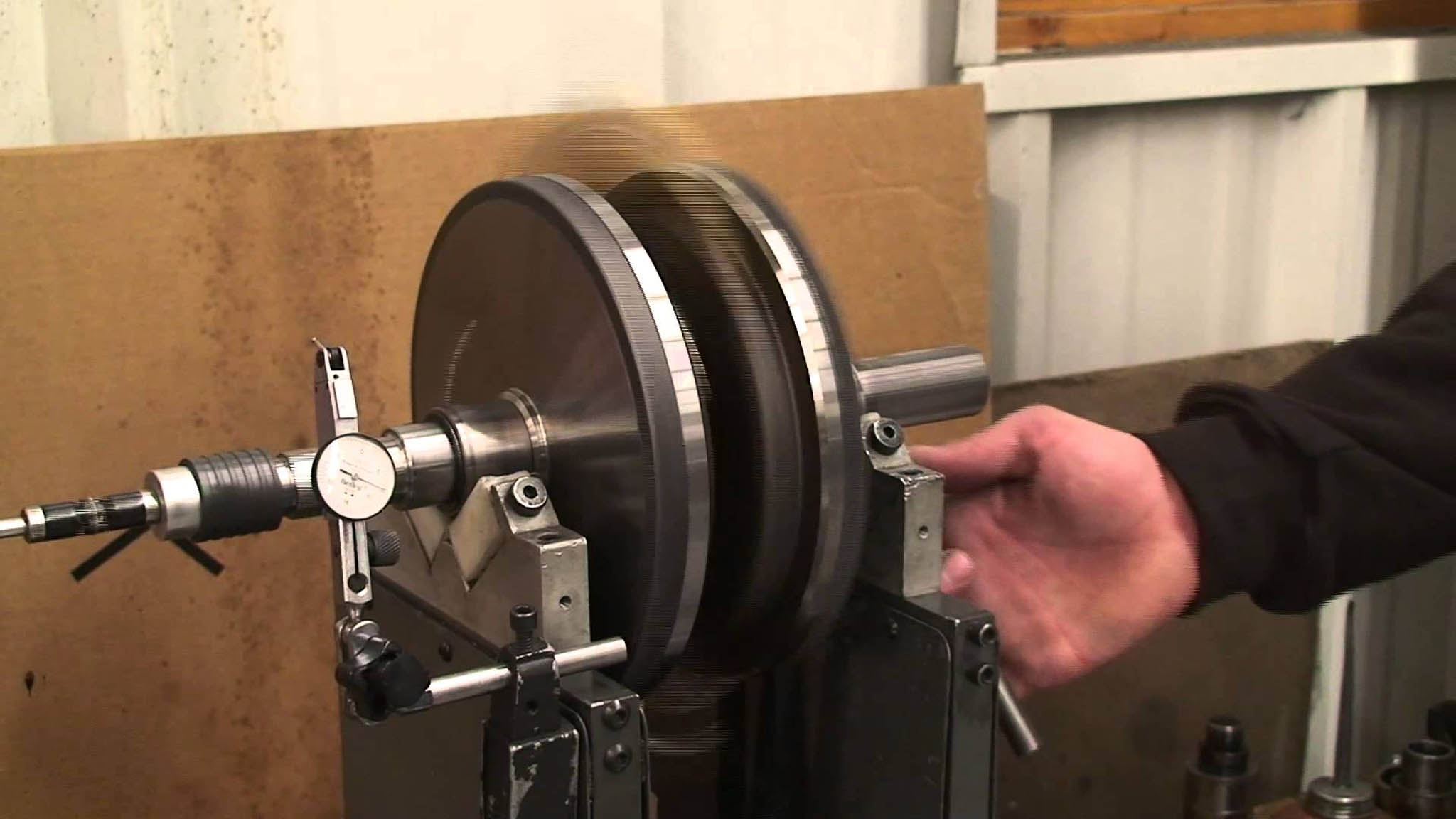

We manufacture some of the very best Dynamic Balancing Machines on the market, so naturally, there’s no better place to outsource your precision Industrial Balancing Work. We can even handle oversized parts and components up to 1,000 pounds, as much as 84” (2133 mm) long and 24” (609 mm) in diameter.

Tight Tolerances and Precision Balancing for

Parts and Components.

If your part or component rotates, then it needs to be properly balanced to minimize wear and to perform safely at peak efficiency. Fentech’s Dynamic Balancing Equipment is designed to handle the extreme needs of high-precision balancing for automotive and racing engine crankshafts, so it’s likely that our equipment can handle almost any industrial part or component balancing application you might have. We can achieve unbalance resolution as tight as +/- 0.2 gm/inch, angle resolution up to 120 divisions/rotation (3.0) degrees and angle repeatability up to +/- 1 division.

Correcting Unbalance in Rotating Parts.

There are many rotating parts and components that require precision balancing as a part of their manufacturing or finishing processes. The following list contains just a few of the items we can balance for you. If you don’t see it in this list, Contact Us. It’s likely we can help with any of your precision dynamic balancing needs.

- Fans / Blowers

- Pulleys

- Armatures

- Impellers

- Electric Motor Rotors

- Compressor Rotors

- Crankshafts

- Flywheels

- And more!